Asbestos Survey and Sampling

Professional Material Analysis & Documentation

The survey consists of collecting material samples at various locations throughout the area. The samples will be analyzed by Polarised Light Microscopy (PLM), or Phase Contrast Microscopy (PCM) from a Reliable Laboratory in Dubai or the USA certified to conduct asbestos material sample analysis. Polarised Light Microscopy will determine the presence, type, and percentage of asbestos contained in the sample.

In order to be fully certain that the area does not have ACM's (Asbestos Containing Materials) in their Buildings, Schools, Plants or vessel, it is recommended that all of the samples that are collected during the survey should be submitted to the laboratory for analysis. These materials should be presumed to contain asbestos until proven otherwise through laboratory analysis.

Common ACM Locations:

- Roof Panels, Roof tiles, Roof Panel Gaskets

- Packing, PCB's, Fire Blankets

- Sinks, Cement, Fume Hoods

- Pipe Insulation, Surfacing (Artex)

- Thermal Insulation, Floor Tiles, Mastic (Glue)

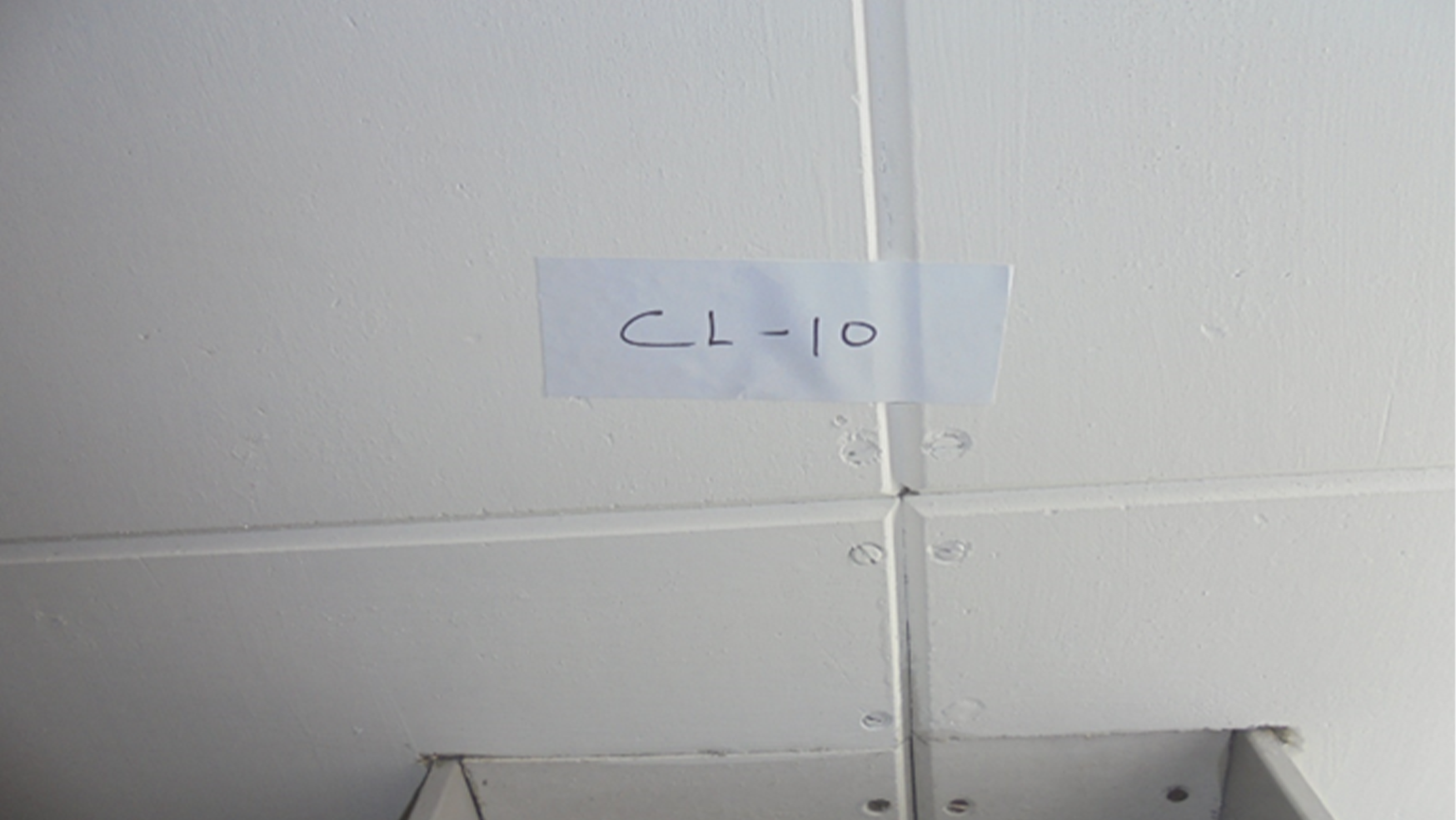

If you desire a full set of photographs will be taken during the survey documenting the location of all the areas that will be checked and inspected.

A survey will be done as completed in accordance with existing US Environmental Protection Agency (USEPA) and US Occupational Safety and Health Administration (OSHA) standards for asbestos.

Survey Process

- Initial site assessment

- Material sampling collection

- Laboratory analysis (PLM/PCM)

- Detailed reporting

- Photographic documentation

- Compliance verification

Key Survey Benefits

- Comprehensive material analysis

- Professional laboratory testing

- Detailed documentation & reporting

- Compliance with USEPA & OSHA standards

- Photographic evidence collection

- Risk assessment & safety planning

Before and After Comparison

Transformation Through Professional Asbestos Management

Before: Asbestos Contamination

Initial Condition: Area contaminated with asbestos-containing materials requiring immediate attention and professional intervention.

After: Safe and Clean

Final Result: Area completely cleaned, decontaminated, and safe for occupancy with all asbestos materials properly removed.

Professional Asbestos Removal Process

1. Sampling & Testing

Professional sampling and laboratory analysis to identify asbestos presence

2. Area Preparation

Proper masking and containment setup to prevent contamination spread

3. Safety Setup

Installation of decontamination units and critical barriers

4. Final Cleanup

HEPA filtration and thorough decontamination for safety compliance